Share

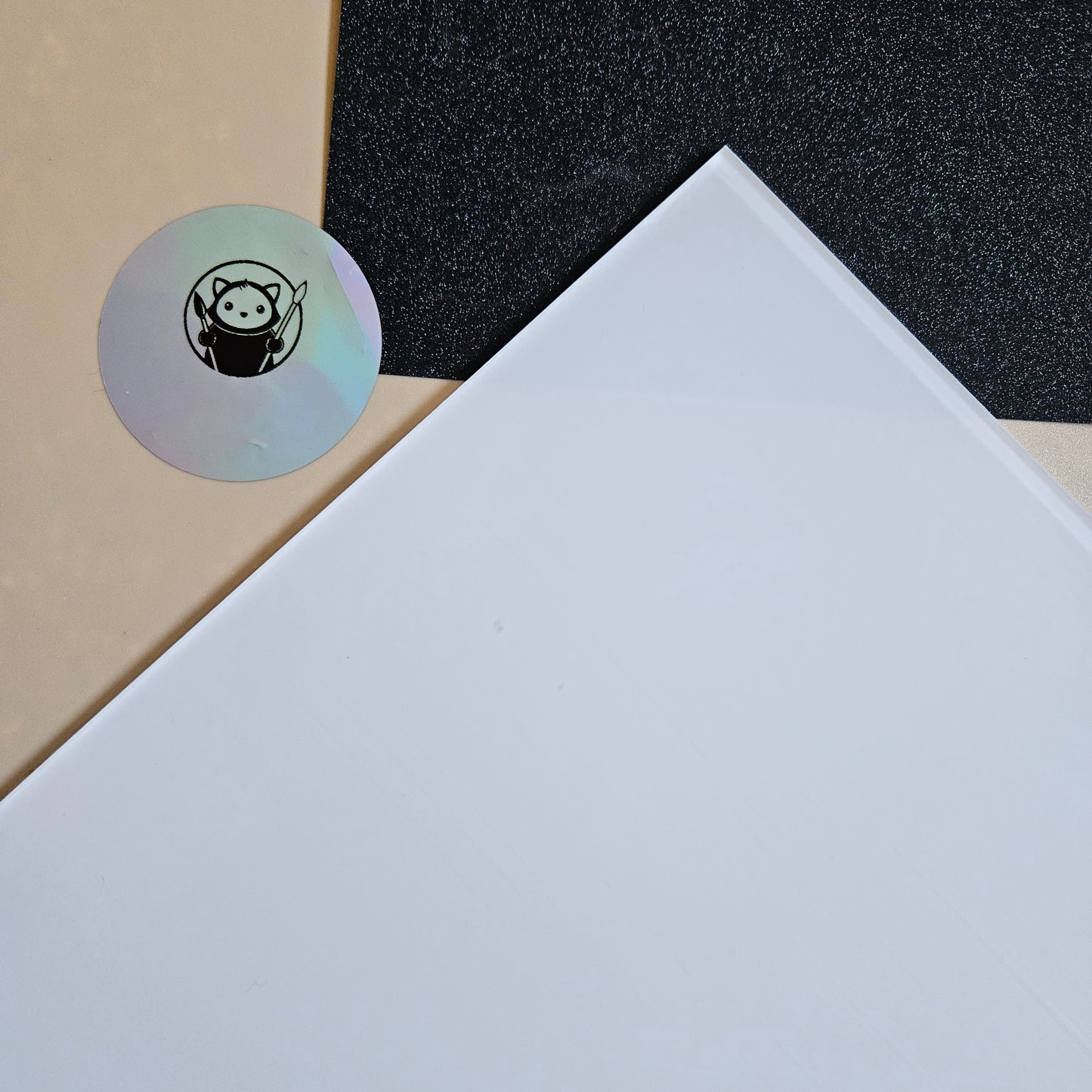

Sublimation Acrylic - Clear

Sublimation Acrylic - Clear

Couldn't load pickup availability

What is Sublimation Acrylic?

Made for sublimation printing, this premium acrylic sheet offers vivid colours, sharp detail, and a glass-like finish. The matte white backing ensures bold, opaque designs, while the glossy clear side displays them with striking clarity. Ideal for signage, photo panels, ornaments, awards, décor, and more.

Specifications:

- Material: Cast Acrylic

- Opacity: Opaque

- Side 1: Matte white (sublimation side)

- Side 2: Glossy clear (display side)

- Thickness: 3 mm (1/8")

- Masking: Protective plastic film

2. How to Sublimate on Sublimation Acrylic

- Place the acrylic, with the clear, glossy side down, for cutting if using a laser.

- Remove the protective plastic film from both sides.

- Print your design on sublimation paper with sublimation ink (do not mirror).

- Position the acrylic with the matte white side down onto the printed design.

- Secure with heat tape and sandwich between sheets of white butcher paper.

- Place the acrylic and paper in the press, with the sublimation paper side up, facing the heating element of your press.

- Press, then immediately place under a flat, heavy object to prevent warping.

- Peel while still hot for best results, and allow to cool completely before use.

3. Recommended Press Settings

- Temperature: 182°C (360°F)

- Time: 60 seconds

- Pressure: 130 lbs (medium-firm)

- Peel: While hot

- Cooling: Place under a weight to keep flat

Notes:

- Different heat presses may require 5–10°C hotter adjustments.

- Always test on a small patch before full production.

- Use butcher paper to protect both the press and the heat pad during sublimation.

Important Notes

Important Notes

Confirm diode laser compatibility prior to usage. Diode lasers are incompatible with transparent and blue acrylic materials.

Colors may vary slightly due to screen differences. We try our best to show them accurately!

Expect slight size variation (±½") and up to ±20% in thickness. Edges may be rough or chipped from cutting.

The PE film on both sides protects the acrylic during shipping and handling. It is laser-safe, but if it's scratched or damaged, it can be replaced with paper masking for better cutting results. Remove the masking after the project is completed for a clean, glossy finish.

Care Instructions

Care Instructions

- Clean with a soft cloth and mild cleaner.

- Avoid using harsh chemicals (like ammonia-based cleaners).

- Store away from direct sunlight and extreme temperatures.

- Handle carefully to prevent scratches and chipping.

- Store vertically on a sturdy rack (at no more than a 10-degree angle) or flat with smaller pieces stacked on top to avoid warping.

What You Can Do With It

What You Can Do With It

- Laser cut clean shapes using lasers Glowforge, xTool, OMTech, Gweike Cloud, Thunder Laser, and more

- Score or engrave fine details for signage, nameplates, ornaments, and custom branding

- Heat-form into curves or 3D acrylic displays with a strip heater or heat gun

- Drill smooth holes for hardware, earrings, signs, or light fixtures

- Paint, dye, or ink the surface for custom colour effects

- Apply vinyl decals or permanent adhesive lettering

- Use UV printers like EufyMake, Mimaki, or Roland for direct full-colour printing

- Add foil accents or hot stamping for a luxurious metallic look

- Polish edges for a professional, high-gloss glass-like finish

- Bond pieces securely using acrylic adhesives

- Layer colours and shapes to create dimensional designs and art